Gentoo Group

- LocationSunderland

- Completion DateNov 2022

The Gentoo heating upgrade scheme also included further improvements in the tower blocks, such as the installation of sprinklers, upgrades to the incoming electricity supply and upgrades to fire alarm and detection systems.

David Broom, Commercial Director at Kensa, said:

Electrification of heat with ground source heat pumps not only makes buildings safer and cheaper to run, but also immediately reduces carbon emissions, and more importantly puts UK homes on the pathway to Zero Carbon as grid infrastructure is further decarbonised.

Nigel Wilson, Chief Executive Officer, Gentoo Group, said:

Gentoo is committed to providing safe and affordable housing for its tenants. This pioneering heating system provides heat and hot water at a much-reduced cost, using natural heat from the ground, and delivers real savings for our tenants. This is just one of many improvements we are committed to making in our high-rise blocks which will ensure our residents stay even safer in their own homes in the future.

Andrew McIntosh, Regional Managing Director, ENGIE

We have a great partnership with Gentoo and were delighted to help bring this innovative and energy efficient solution to all North Tower residents involved in this project, providing them with a modern sustainable heating system and enhanced fire safety features.

The gas boilers in the tower blocks were all over 20 years old and at the end of their useful life. Along with changing building regulations and environmental concerns encouraging a move away from fossil fuels, staying on gas wouldn’t have been a simple switch for Gentoo. A C-duct flue system ran right through the middle of each tower block; modern boilers wouldn’t connect to this system, meaning the gas emissions wouldn’t dissipate properly.

Gentoo therefore considered many alternative options; including air source and biomass. The incumbent boilers were already on a decentralised system, so that tenants had individual control over their heating and Gentoo didn’t have to worry about split-billing or metering, or overheating of communal areas.

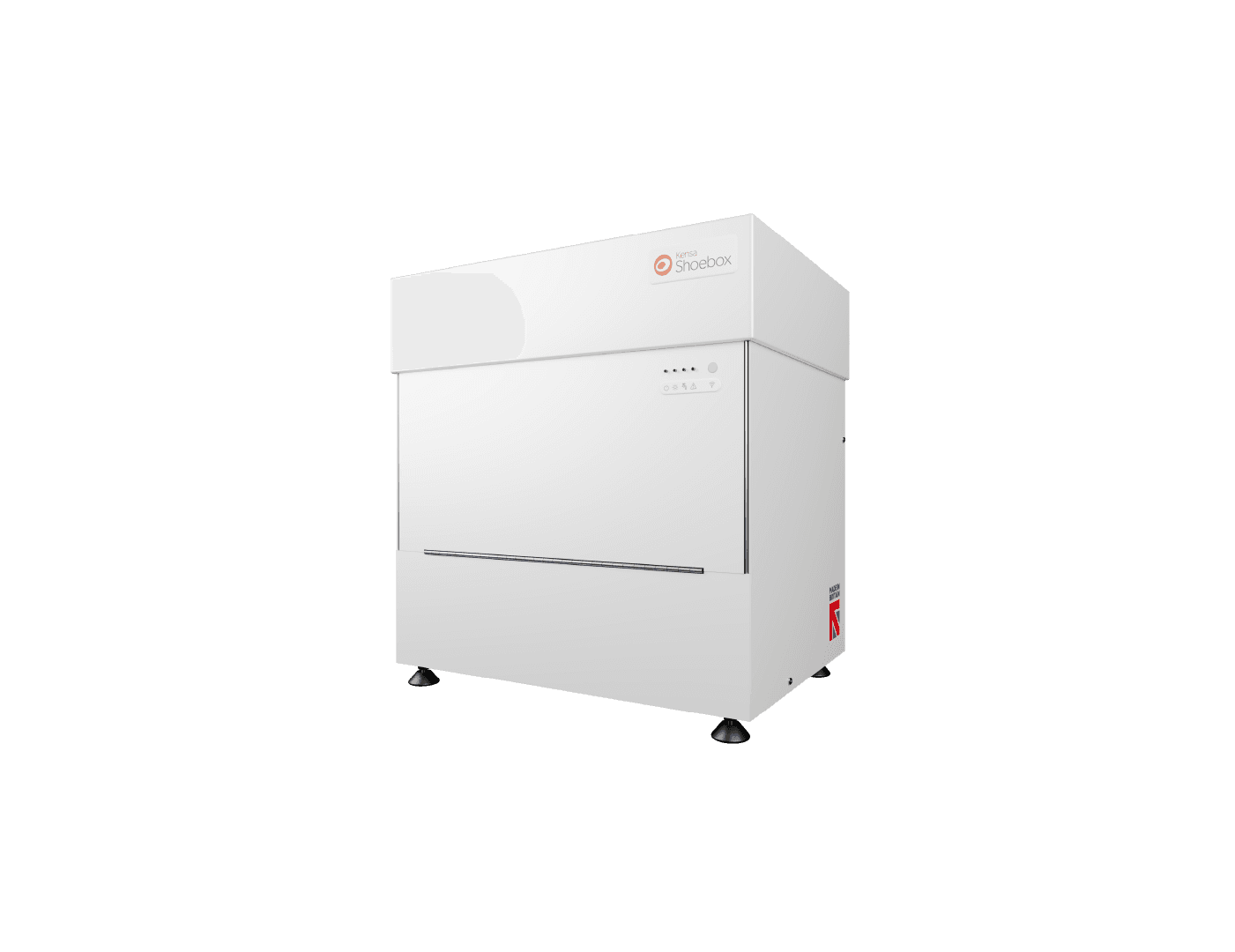

Kensa  ShoeboxProductShoebox ground source heat pumps installed inside each flat and connected to a shared ground loop array were able to closely mimic their existing system, with equivalent running costs due to their high efficiencies and low maintenance requirements. And they reduced carbon emissions by an enormous 70% – a figure that will become even more pronounced as the grid further decarbonises.

ShoeboxProductShoebox ground source heat pumps installed inside each flat and connected to a shared ground loop array were able to closely mimic their existing system, with equivalent running costs due to their high efficiencies and low maintenance requirements. And they reduced carbon emissions by an enormous 70% – a figure that will become even more pronounced as the grid further decarbonises.

Kensa also supplied an  EvoProductEvo ground source heat pump in each of the 7 tower blocks to heat the ground floor communal areas which contain a manager’s office and launderette.

EvoProductEvo ground source heat pump in each of the 7 tower blocks to heat the ground floor communal areas which contain a manager’s office and launderette.

As the old boilers were combi boilers without mains pressure hot water, pairing unvented cylinders with the ground source system would have required installing more pipework for the discharge – a large task across 7 x 13 storey tower blocks!

To avoid this, Gentoo decided to use UniQ SunAmp thermal storage heat batteries for hot water provision. In an industry first collaboration, heat from the Shoebox heat pump charges a non-toxic material inside unit that can change state from a solid to a liquid and back again, storing and releasing heat like a battery. As hot water is produced by this means, there is no risk from legionella, meaning no annual cylinder safety checks or need for G3 pipework regulations.

The heat demand was high due to the size of the large tower blocks and the cold coastal climate. The urban location meant there was not sufficient space on-site for traditional boreholes. However, geological surveys revealed there was a large untapped aquifer at 60 – 70m depth. The underground layer of chalky limestone in the area was filled with cracks and fissures which allow unlimited amounts of water to permeate, and water is an excellent conductor of heat.

Water source heating is beneficial because the heat transfer rate from water is higher than the ground, increasing the efficiency of the heat pump system. Utilising the aquifer greatly reduced the need for digging or drilling, reducing the cost and duration of the groundworks compared to a traditional installation.

Kensa used open-loop boreholes to extract water from one location, filter this through heat exchangers in the heat pump to absorb energy from the water, and then deposit this cooler water into another location of the aquifer water source at an acceptable distance from the first borehole. Open-loop systems require a license from the Environment Agency and regular testing.

Kensa utilised a double-well pump system for the open-loop boreholes, providing 100% redundancy on possible single-point failures, removing any concerns regards maintenance and defects. Kensa also put in place a programme of ongoing maintenance of the pumps and plate heat exchangers to ensure they are always clean and operating correctly to combat the high levels of iron oxide in the water.

Kensa’s system also gives remote access to the pumps with real-time diagnostics to monitor the system’s performance. In the event of future maintenance or in order to run the required regular Environment Agency tests, an electric boiler can quickly and easily be connected in each tower block, ensuring residents do not go without heating or hot water.